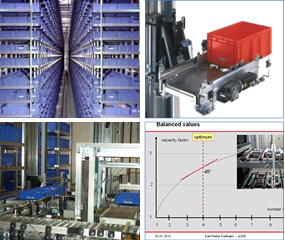

Multiple load handling attachments are employed to increase the performance of an automatic storage and retrieval crane (storage-retrieval operations per hour). Basically, please consider the following when using multiple load handling attachments:

· An increase by factor x will never result in the performance being x times as high.

· The increased performance depends on the storage strategy, but also on the constructive design of the AS/RS.

Rule of thumb:

· Using 2 load handling attachments ---> improved performance by factor 1.7

· Using 4 load handling attachments ---> improved performance by factor 2.5

· Using more than 4 load handling attachments is not recommended

As a rule, the width of the AS/RS layout increases and is a criterion for the efficiency of the solution

Special requirements when using multiple load handling attachments

When designing and dimensioning, care must be taken to ensure that for twin-mast cranes the load handling attachments are fixed to different masts such that they can be positioned independently of each other in y-direction. However, what is decisive is that the storage strategies are adapted to both the logistical tasks and to the technological properties of the load handling attachment. Example: When considering the sequence of the later stock removal already during storage in a JIT/JIS buffer (e.g. Dräxlmaier), hence two storage locations can be processed simultaneously (parallel access of the two load handling attachments).