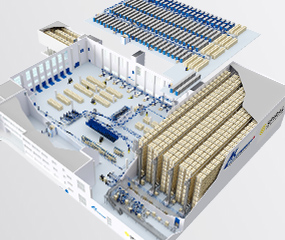

Klinkhammer accompanies you in four steps to the logistics concept, that is manufacturer and technology-neutral, and, as a logistics consultant, specialises in all phases of logistics planning. Optimised in terms of cost-effectiveness and feasibility, you will receive your tailor-made solution for the partial or full automation of your logistics processes. If you wish, we can also put your logistics trades out to tender and accompany you through the selection process. More about logistics planning

Logistics consulting that is independent of manufacturers and technologies is the basis for a successful logistics concept. It identifies weak points and potential savings, streamlines processes, optimises material flows and ensures that the most cost-effective and sensible logistics solution is developed for the customer. The aim is to optimise logistics in order to create competitive advantages over other companies. Our long-standing logistics experts will support you in all phases of logistics planning.

The foundation of a logistics consultancy and every logistics concept is a comprehensive data analysis. This includes the recording of the current situation as well as the analysis of the current and future expected quantity structures. At the end of the first phase of the logistics consultancy, the objectives for further planning are jointly defined.

Current situation assessment during the logistics consultation

Quantity structures

Formulation of logistics consulting goals

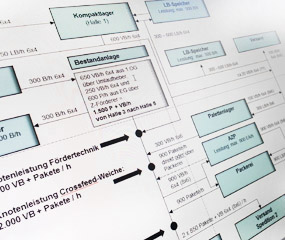

Based on the results of the data analysis and the formulated planning objectives, potentially suitable solution concepts are developed and compared within the framework of the logistics consultancy. At the end of this phase of the logistics consultation, the advantages and disadvantages of the rough concepts are highlighted in order to be able to make a decision for which variant a logistics concept will be created in the next step.

Each rough concept includes

Evaluation criteria for logistics consulting

This phase of the logistics concept is concerned with the elaboration of the preferred solution variant at the end of the rough concept phase. At the end of this phase of logistics consulting, a logistics concept is available that can be implemented taking into account the influencing variables. For this logistics concept, the investment can be estimated as a first approximation and a non-binding realisation schedule based on empirical values can be drawn up.

The logistics concept includes

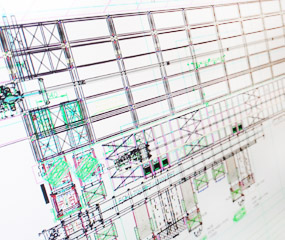

The project planning phase of the logistics consultancy involves the detailing of the agreed logistics concept. Klinkhammer presents the procedure and the results in a final presentation. All results of the detailed planning are also made available in a report in the form of a final presentation. As a final result of the logistics consultancy, you will receive a binding fixed price offer including a realisation schedule.

Results of the logistics consultancy: