With more than 20 fashion brands, BESTSELLER offers a broad range of fashion clothing and accessories for children, young, and adults around the world. In the financial year 2021/2022 the Scandinavian fashion company BESTSELLER reported a 33% increase in sales. Today products are available in 70 countries across the world. The wholesale business sells the products to more than 17,000 multi-brand and department stores globally. There are approximately 3,000 branded BESTSELLER retail stores in 32 countries globally. BESTSELLER owns approximately 2,400 of these stores, while the other stores are operated by partners.

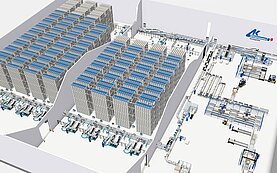

Due to increasing demand and to ensure existing delivery standards, an existing logistics center was automated at the Taulov logistics site in Denmark. An Exotec system designed for around 51,000 trays was installed as an automatic replenishment. To ensure high system performance, 79 Skypod robots are used, which are responsible for storage and transport to the order picker.

"A big achievement of the project is the implementation of a complete Exotec storage system, a new warehouse management system and the warehouse control systems in less than a year. It is a great example of the good teamwork between system integrator Klinkhammer, Exotec and BESTSELLER”, explains Jakob Skødt Larsen, Product Owner at BESTSELLER TECH.

High degree of automation in carton and pallet handling

The Exotec system connects carton, container and pallet conveyor technology with goods receipt and shipping. A high degree of automation in carton handling with automatic erector, volume reducer and sealer as well as labelling reduces throughput time. Goods receipt will also be automated in a second construction phase in 2023 and equipped with a robotic system for depalletizing and automated carton opening. The robots pick cartons of different sizes from the pallet and place them on a conveyor belt. During the automatic carton opening, a size scan is carried out and the robot cuts an opening on the top of the carton, from which the picker later picks the goods. Robots are also used for palletizing in shipping. The palletizing robot recognizes mixed carton heights and automatically stacks them on a pallet, which is then automatically wrapped and transported for loading. KlinkWARE is used as the material flow computer. The software takes over the optimal and high-performance material flow of the entire system and communicates with the control technology of the pallet and carton conveyor technology, the storage system and the packaging and unpacking lines. The KlinkVISION visualization system enables permanent process visualization down to the sensor level and thus rapid alarm diagnosis in the warehouse.

“Investment in logistics infrastructure and technology to support our growth, and to position BESTSELLER as an industry leader in logistics and technology is very important. Our warehouses have been working very hard to keep up with the demand from our brands, so we are very pleased with the implementation of skypod robots”, explains Tonni Jensen, Project Manager at BESTSELLER.

The Heart is the shuttle-Robot-System

BESTSELLER opted for Klinkhammer as system integrator to link a wide variety of automated systems. The heart is an Exotec system with Skypod robots. It can be flexibly adapted to changing products, variants, order situations and order structures and is used for storage, order picking and at the same time as an order consolidation buffer. The scalability is the special feature of the Exotec system. Shelves can be expanded during ongoing operations, picking stations and Skypods can be added. The robots form an intelligent combination of freely navigating vehicles for transporting containers on floor level and vertically moving shuttles within a 10,50 meter high rack. The Skypod robot climbs up the shelves independently to remove the trays, which weigh up to 30 kg, and serve them at an ergonomic grip height at the picking station. The picking dialogs are displayed to the employee on the screen, which is at eye level. The workstation is equipped with a put-to-light display for four target cartons, enabling fast and secure multi-order picking. A conveyor system loop automatically transports the empty target cartons to the station and, after filling, to the automatic carton volume reducer and the sealer.

As an all-included service package, Klinkhammer takes on full service for the entire system with its own on-site staff. This ensures smooth system operation and rapid troubleshooting in the event of a fault. The service also covers maintenance and spare parts handling.