Automated Small-Parts Warehouses operators used to have only two choices: Conventional automated storage and retrieval cranes (AS/RS) with approximately 120 double cycles per hour and common shuttle systems with a capacity of up to 1,000 double cycles per hour. This gap is closed by multilevel-shuttle system KlinCAT®. With a lifting height of around 1.5 meters KlinCAT® is able to reach up to 9 tote levels and can be used like a shuttle on several levels above each other. In a single-aisle, double-deep automated small-parts warehouse with a height of 12 meters and a length of 35 meters, KlinCAT® achieves more than three times the performance of conventional storage/retrieval cranes.

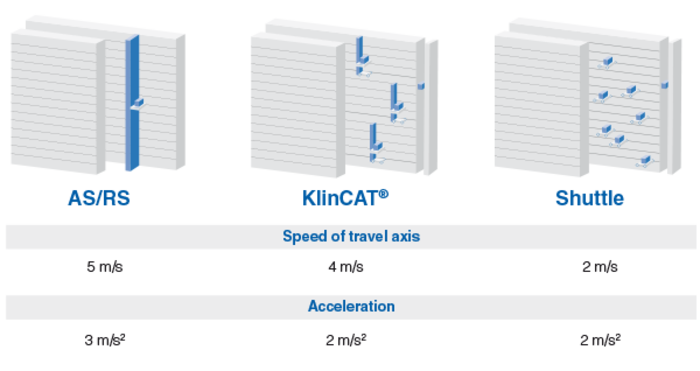

KlinCAT® stands out for its compact design and its low weight and substantially contributes to an enhanced dynamics and a higher throughput. When comparing the drive parameters to automatic storage/retrieval cranes featuring a speed of around 5 m/s and to shuttle systems featuring a speed of around 2 m/s, KlinCAT® reaches powerful 4 m/s. Other advantages: Small bottom and top approach dimension to ensure a high storage density, an innovative, energy-efficient drive concept and low maintenance and investment costs.

The Klinkhammer Group offers from a single source all software modules being necessary for an efficient, fully automated warehouse and optimizes your flows of material. From the control of the KlinCAT® (PLC) to warehouse management systems, material flow control, visualization, interface connections and service 24/7.

Goods to be conveyed

Totes, cardboard boxes, trays

Drive speed

4 m/s at an acceleration of 2 m/s2

Lifting height

Up to 1.56 m, max. 9 tote levels

Payload

2 x 30 kg / 1 x 50 kg

Drive concept

Siemens Sinamics S120, decentralized

servo drives with DRIVE-CLiQ

Energy transmission

3-pin conductor line

Tote sizes

400 x 600 / 600 x 800 mm

Control

Siemens S7, programming: Klinkhammer

Approach dimension

Bottom: 260 mm, top: 330 mm