160,000 articles, 40,000 tools and machines permanently in stock

Since the company's foundation in 1961, Spiral Reihs & Co., an owner-managed family business headquartered in Vienna, has been focusing its activities on high-quality tools and a broad range of services combined with a strong customer orientation. The product portfolio consists of around 160,000 articles of which 40,000 are permanently available from stock. The extensive range of products and services of Spiral comprises tools, machines, work safety equipment, chipping machines, clamping and measuring devices, industrial and workshop supplies, repair services as well as measuring and testing services. The products are supplied by quality manufacturers worldwide and to some extent exclusively fabricated for Spiral.

We only deal with tools that really convinced us

“We know our manufacturers, suppliers and customers. We only deal with products that really convinced us” emphasizes Christian Fink, member of the Board of Management of Spiral Reihs & Co. KG. “That’s why our customers get high-quality products with an excellent price/performance ratio and are competently serviced and advised by motivated and friendly Spiral staff members. We live our philosophy “much more than anything” not only by guaranteeing a delivery rate of 99%, but we also offer service, maintenance, special procurements and a great deal of knowhow and consultancy services in the field of industry 4.0.

Planning security and profitability analysis

Due to the continuous company growth the current logistics center of Spiral Reihs & Co. KG is reaching its capacity limits. To be able to provide customers with tools even more rapidly and reliably, the company sought advice as to warehouse automation, process optimization and digital networking. Klinkhammer took on the planning activities that included logistics analysis, comparison of variants and profitability assessment and finally the preparation of the ready-to-use overall concept and the tender documents. As general contractor for intralogistics Klinkhammer won the contract for coordinating the single assembly sections, programming the plant control system and for the warehouse management software including the support when going live.

Focusing on future orientation and high adaptability of the logistics solution

The possibilities of using the old building and of retrofitting the existing site were carefully analysed, but these ideas were not followed up due to the strong growth and forward-looking aspects. When assessing the profitability of the new building on the greenfield, the following aspects were decisive: entire service life, profitability, productivity, storage capacity, material, personnel and time factors, investments and amortization as well sustainability. Within its scope of innovation management, Klinkhammer provided also support when applying for funding. “The solution was not only intended to meet the current requirements of in-house logistics, but should be also able to react and adapt to future developments. So, already at this stage, several stages of expansion have already been planned ahead”, explains Theodor Gartner, project manager of the Klinkhammer Group.

System performance and intelligent process linking in the “Smart Warehouse”

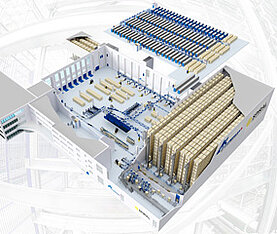

The new logistics center incorporates an automatic pallet high-bay warehouse as well as conveyor technology for pallets and totes, an automatic order consolidation buffer, a drawer system for small parts, shelf storage system, cantilever warehouse and lift warehouse, several special warehouse sections as well as the goods in and shipping zone. The system performance of the four storage and retrieval cranes in the pallet high-bay warehouse with around 9,184 storage locations totals to around 120 double operations per hour. Connected to the high-bay warehouse, there is a pre-zone for the picking of large quantities and bulky goods as well as for ensuring replenishment to the other order picking areas. For optimizing and raising efficiency of the flows of goods the warehouse is equipped with automated tote conveyors that connect all key areas. These conveyors connect 18 work stations in the goods-in, returns processing and packaging section, four packing stations, four picking stations for small-parts picking, the empty tote buffer and an automatic order consolidation buffer as well as the workshop and the shop. In the next expansion stage, another four order picking stations and four additional packaging stations as well as a step-by-step upgrade of the shelf storage system and the drawer system have been already preplanned. Given the peaks to be expected, the conveyor sections have been dimensioned and designed such to meet system performance requirements of around 600 totes per hour. To reflect the volume flows occurring and the simultaneous supply of empty totes, eight lifters with the correspondingly high capacity are going to be installed to connect the empty totes and order picking totes sections on different levels and to configure them such to meet the performance requirements.

Top order picking quality for small parts

A modular shelving system featuring around 14,880 tote storage locations and a drawer system with around 4,340 drawers guarantee fast access to the assortment boxes and small parts. One drawer can carry a weight between 75 kg and 200 kg. The tote conveyor technology links the shelf storage system, the drawer system and the high-bay warehouse with the packaging, goods-in and outgoing goods area. At four stations along the conveyor section the goods to be stored are taken off and the tote is stored randomly in empty available shelf compartments. The warehouse management system with the material flow control system KlinkWARE® ensures the necessary transparency in the new Spiral logistics center and represents the heart of digital networking. The order picking process is supported by a pick-by-voice system to increase the picking performance and to enhance the order picking quality. Beyond that, a lift warehouse section offers the advantage of a fast and compact access to the micro parts of the product line. Special warehouses for bulky goods, long items and heavy-duty pallets as well as aerosol dispensers are also held and managed in the KlinkWARE® Warehouse Management System´. The automatic order consolidation buffer for consolidating orders with several totes is connected via a bypass to the feed-in line for packaging and is able to store and retrieve up to 120 totes per hour. Its buffer capacity comprises around 784 totes. Additionally, the packing stations offer the possibility of merging bulky items and goods in the tote to build one shipment. “By optimizing the process workflow and thanks to the anticipatory logistics planning we managed the leap into the smart warehouse for tools and machines according to Industry 4.0” explains Dr. Dirk Liekenbrock, head of logistics planning at the Klinkhammer Group.

Data and Facts:

- Analysis, planning and realization of the logistics center by the Klinkhammer Group

- Funding consultancy

- 4-aisle automatic high-bay warehouse in silo-type design, 9,184 pallet storage locations

- 800 totes buffer capacity in the automatic order consolidation buffer

- Drawer system for 4,340 drawers

- Shelf storage system for 14,880 totes

- KlinkVISION® plant visualization

- Klinkhammer warehouse management system and material flow control KlinkWARE®

- Aerosol dispenser warehouse, lift warehouse, special warehouse and cantilever warehouse section

- Shipping zone with consolidation and packing zone

- pick-by-voice picking process

- 18 work stations in the goods-in, returns processing and packaging section, four packing stations and four picking stations