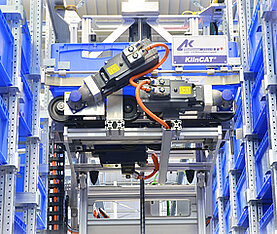

Nuremberg, 09.03.2016 - The Klinkhammer-Group presents at this year's LogiMAT, in hall 1, booth C46, its new multilevel shuttle KlinCAT®. This warehouse vehicle is a high-performance hybrid system in lightweight design that combines an automatic storage/retrieval crane and a shuttle system, featuring a drive axis speed of 4 m/s and an acceleration of 2 m/s2.

More performance at less investment costs

Considerably increased performance at similar capacity - this is what shuttle systems offer compared to conventional automatic storage/retrieval cranes. Depending on the configuration level, however, this will entail a much higher technical effort and investment volume for a warehouse system. With the multilevel shuttle system KlinCAT® by Klinkhammer this is completely different: "Our objective was to develop a powerful and efficient system while keeping the investment costs as low as possible in relation to conventional shuttle systems" - this is how Frank Klinkhammer, Managing Director of the Klinkhammer Group, explains the idea behind the new development. KlinCAT® is a project that was sponsored by the Bavarian State Ministry.

Each KlinCAT® can reach up to 9 container levels

KlinCAT® is an intelligent combination between automatic storage/retrieval carne and shuttle. With a lifting height of around 1.5 m KlinCAT® is able to reach up to 9 container levels and can be used like a shuttle on several levels above each other. Thus, it can be scaled almost without limit. The load handling attachment of the device has been designed for cartons, trays or containers with the basic measurements of 300 x 400 mm, 600 x 400 mm or 800 x 600 mm at a maximum weight of 50 kg per loading device. The low height allows a compact design and the use of a zero backlash spindle drive for the lifting mechanism. When comparing the drive parameters to automatic storage/retrieval cranes featuring a speed of around 5 m/s and to shuttle systems featuring a speed of around 2 m/s, KlinCAT® reaches powerful 4 m/s. The acceleration amounts to 2 m/s2 which is comparable to shuttle systems available on the market.

Hybrid system

With this hybrid solution, the Klinkhammer Group for the first time is heading for the in-house development of shuttle systems. "What has been lacking on the market so far is an automated small-parts warehouse with a good price-performance ratio and high throughputs. We continue to observe a strongly rising demand for an interim solution, a kind of hybrid between automatic storage/retrieval crane and shuttle system", confirms Frank Klinkhammer. "KlinCAT® exactly meets these requirements. "Thanks to the combination of proven, cost-effective AS/RS and highly-performing shuttle technology, the in-house development contributes to a significant performance boost. The system therefore is excellently suited for high-performance order picking systems and order consolidation buffers.

Optimized price-performance ratio

The good price-performance ratio in comparison to a shuttle system is not only the result of a smaller number of warehouse vehicles. Also the clear and manageable complexity of the racking steelwork and of the logistics system's overall control makes the KlinCAT® such an attractive system. In case of several shuttle systems or KlinCAT®s above each other the systems are connected by means of a vertical lift. In a system comparison for a single-aisle, double-deep automatic small parts warehouse with a height of 12 m, a length of 35 m and a container size of 600 x 400 mm shuttle systems and the multilevel shuttle KlinCAT® achieved three times the performance compared to conventional storage/retrieval cranes. Thereby 2 vertical lifters were assumed for KlinCAT® and the shuttle systems. The investment comparison reveals that, compared to an automatic storage/retrieval crane, the multilevel shuttle KlinCAT®, despite performance increase, requires only around 1.6 times the investment volume whereas a level-changing shuttle system costs 2.3 times as much. The price for a level-bound shuttle system in its full version would be even significantly higher.

Lightweight construction: Almost 50% weight reduction of the telescopic table

KlinCAT® achieved an important milestone in the lightweight design of warehouse vehicles and simultaneously a throughput increase. The low weight of the telescopic table considerably contributes to greatly improved dynamics. To achieve the specified goal of weight reduction the conventional construction of a telescopic table with belt conveyor has been completely put to the test and trimmed for an optimized lightweight design. By deliberately leaving out additions that were not required, using more aluminium and redesigning the belt conveyor the weight of the telescopic table including drive could be reduced from more than 150 kg to 80 kg, i.e. by almost 50%.

Small, bottom approach dimension for space-saving shelving design

The small approach dimensions are another highlight of KlinCAT®. The clear space in the shelving system between the top container level of a device and the bottom container level of the device above it, that results when several KlinCAT®s are arranged on top of each other, is optimized by the smallest possible bottom and top approach dimension of the KlinCAT®s. The drives are fitted laterally and not mounted to the bottom side of the telescopic table as with conventional load handling attachments. This way, the bottom approach dimension of the shuttle was minimized and the overall design of the racking system was realized such to be space-saving thus allowing a high storage density and space utilization.

Innovative, energy-efficient drive concept

An innovative drive concept also makes a contribution to the lightweight design. Thanks to the lighter overall design it was possible to use travel and lifting motors with a lower driving power. The energy supply concept to conduct the link of the drive systems and components via conductor lines networks all drives of one aisle reduces and the number of on-board KlinCAT® components. For KlinCAT®, an energy-efficient spindle drive is used which consumes almost no energy when idle compared to a belt drive. This way, the energy efficiency is further optimized in the context of "Green Logistics". The lightweight design and the energy-optimized structure therefore contribute also to the economic operation of warehouse systems with KlinCAT®.

Low maintenance and operating costs

Compared to shuttle systems, maintenance and operating costs are much lower because of the smaller number of warehouse vehicles. During maintenance of an automatic storage/retrieval crane or in the event of a failure the complete aisle can no longer be reached and a manual access to storage containers is very elaborate and time-consuming due to the large height of the warehouse. With KlinCAT®, a maintenance level is integrated on each drive level which guarantees manual access to the single storage locations and ensures that maintenance activities can be carried out much faster and more purposefully. This way, highest availability is achieved.

Control and software

The Klinkhammer Group offers from a single source all software modules being necessary for an efficient, fully automated warehouse and optimizes your flows of material. From the control of the KlinCAT®s (PLC) to warehouse management systems, material flow control, visualization, interface connections and service 24/7.