Regardless of barrels and big bags or unmixed pallets with packaging material – at Sanofi’s production site in Lüleburgaz/Turkey more than 1,000 euro-pallets daily are moved over the conveyors installed in the incoming goods and shipping department. The Sanofi group, headquartered in Paris, is one of the world’s leading healthcare suppliers. According to the IMS, Institute for Healthcare Informatics, Sanofi is the fourth-largest pharmaceutical company around the world and has been renowned in the ambitious emerging markets for a long time. The expansion of the product portfolio resulted in an increasing need for new conveyor technology solutions allowing to smoothly handle pallets with a weight of up to one ton.

In addition to the over-the-counter drugs (OTCs), Sanofi also focuses on solutions for diabetes, vaccines and innovative drugs in therapeutic areas of oncology, thrombosis, cardiovascular diseases, central nervous system and internal medicine. In Germany, Sanofi is the fourth-largest manufacturer of pharmaceutical products. The products Maaloxan®, Bronchoforton®, Mitosyl®, Ibuflam® and Heumann Teas are only some of the products belonging to the portfolio. From Lüleburgaz, products are exported to 40 countries.

The Klinkhammer Group has been awarded the contract by Sanofi, Turkey, to plan and realize the conveyor technology, including two vertical conveyors, one pallet changer as well as the complete control and visualization system. In April 2017, the project was implemented. “Because of very strict quality specifications and requirements according to GMP in the pharmaceutical sector, pallets have to be changed. The highly performing logistics system by Klinkhammer puts up to 60 pallets per hour from wooden to hygiene pallets or vice versa”, says Hakan Kaya, logistics manager of the Industrial Operations division of the Sanofi site in Turkey.

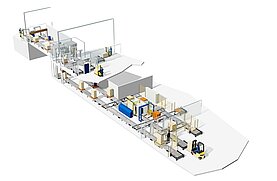

Making investments in new conveyor technology had become necessary as additional product lines have complemented the already manifold range of products. At Sanofi, not only liquid and solid pharmaceuticals are manufactured at one site, but also ointments. These three production areas are now connected via a conveyor bridge. The core of the system is a pallet changer featuring a capacity of up to 60 pallets per hour which provides the production areas with raw, auxiliary and operating material. Thanks to the optimized conveyor section, finished goods are transported completely automatically from the productions areas to the central shipping department. Besides the mechanical components, the Klinkhammer Group also realizes the control of the system as well as the visualization and material flow control. “The material flow optimization helps to increase the throughput of goods while reducing manual operations. This considerably increases the efficiency of the logistics system”, explains Hagen Schumann, Authorized Representative and Head of Sales and Consulting of the Klinkhammer Group.

Data and facts on the system:

- 200 m of conveyors

- Feed-in/pick-up points

- Pallet changer

- Cover sheet dispenser

- 2 vertical conveyors, 2 lifting stations

- Visualization computer

- Planning, installation and commissioning

- Project management