With 50 trucks in its vehicle fleet, Früchte Jork is a connecting link between industrial companies, producers and trade and guarantees precise pick-up and delivery. The company strategy of Früchte Jork envisages lean, efficient and machine-supported order picking and storage in the future. This strategy shall further guarantee continuous growth, segment expansions and the expansion of the market position. Therefore, Früchte Jork decided on a reconstruction and the new construction of a modern logistics center, which is to be carried out in several construction stages. In addition to the new, automated deep-freeze warehouse, the storage concepts for the fresh and dry areas will be implemented in a second construction stage.

With its origins in the traditional fruit and vegetable wholesale trade, the company has developed into a comprehensive fresh produce service provider with a focus on fresh goods, fruit, vegetables, delicatessen and dairy products since its foundation in 1953. At its current location in Isny, Früchte Jork has been operating fresh produce logistics for almost 40 years, which has been continuously expanded since then. Most recently, a hall building for deep-freeze and fresh produce storage and, in 2014, an office building was added to the site.

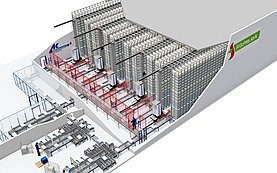

The new building with an automated small-parts warehouse for frozen products is designed as a 5-aisle shelf construction for 25,500 tray storage locations. Trays are used as loading aids in order to be able to flexibly store cartons of various sizes, designs and height classes. The storage and retrieval cranes are equipped with camera technology to visualize the telescope areas and with super caps for energy recovery. The pre-zone circuit connects the storage and retrieval conveyors in the storage area with the picking stations in the logistics area. A climatic separation between the picking area and the deep-freeze warehouse enables flexible handling of the goods. At the picking stations, the infeed and removal conveyor lines are connected via an all-round roller table to guarantee ergonomic handling of the trays. The picking stations are equipped with scales and height control. Adherence to order sequences is ensured by sequencing the source trays at the picking stations.

Based on future growth expectations, the concept for the new deep-freeze warehouse was developed together with the owner family and Klinkhammer. When designing the system, attention was paid to the smallest possible space requirement and energy-efficient storage. Storage capacity, functional and storage areas, picking throughput and processes in the new warehouse and in the existing warehouse were taken into account in the new logistics concept based on the evaluated figures. Deep-freeze warehouses have a number of special features which must already be taken into account during construction and material flow planning. Here it is a matter of maintaining cold chains, complying with food processing regulations and optimizing the spatial conditions. In addition, deep-freeze warehouses require cold-resistant technology. The seals, materials and lubricants used in the machine components must be designed for the extreme temperatures, as must the electrical system. The sensors and control assemblies also have to withstand the freezing temperatures.

Maximilian Jork who has taken over the management from his father Joachim Jork in 2020 explains: „The automated logistics center is an important part of our holistic growth and digitization strategy. The products from the deep-freeze warehouse are transported to the picker via automated storage systems. Compared to manual logistics centers, this significantly increases our picking performance, improves picking quality and shortens walking distances. The workplaces become more attractive and the motivation of our employees increases. “

The warehouse management system KlinkWARE monitors and controls the material flow in the small-parts warehouse. The logistics concept also includes a 24-hour online standby service and preventive maintenance measures, thus ensuring reliable and highly available processes in the warehouse.