Nuremberg / Bautzen. Be it Simson, MZ, IWL, JAWA & Co, AKF is one of the leading online dealers for spare parts and accessories for mopeds and motorcycles from the former GDR. It offers everything a committed two-wheeler and vintage fan could wish for on the road and off-road. After the existing logistics system of Klinkhammer has been operating successfully for 10 years, the intralogistics specialist was commissioned with logistics planning and expansion due to the strong growth in the range. A future-oriented logistics concept for the development at the location in Bautzen in Saxony should be worked out. Eventually, Klinkhammer developed a concept for converting and expanding the existing facility in such a way that everything can be merged smoothly in a new logistics area without affecting ongoing operations.

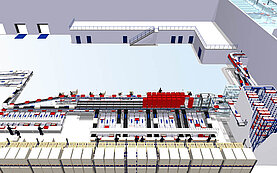

In order to meet the range growth to more than 20,000 items and to ensure fast delivery, the new location is expanded by a new logistics hall and the existing building is expanded by a third floor. The new logistics includes shelf picking with pick-by-voice, an automated order consolidation buffer, a pallet warehouse as well as goods receipt and packing workstations connected by conveyors. Klinkhammer also supplies the system control and warehouse management software. Due to the expansion, throughput can be doubled to around 5000 deliveries per day. At the same time, space was created and the storage area was tripled. Due to the automation of logistics and the expanded range of products, AKF will also be able to fulfill very special requests of the nostalgia bike fans in the future.

Currently, around 12,500 order positions are picked every day and handed over in the dispatch department to transport logistics service providers in around 2,500 deliveries per day. The available space and the existing workstations in the existing building with shelf station picking are already a bottleneck, especially on days with peak orders. In the future, it shall be possible to process 5000 deliveries per day. The logistics concept is divided into three construction stages so that ongoing operations are not affected. After setting up the platform, the shelving and pallet racking system, the new conveyor technology for order picking, incoming goods, packing and outgoing goods will be installed and the 27 new workstations will be connected.

The warehouse management system of Klinkhammer accepts the goods at goods receipt and controls the storage and order picking at individual stations via pick-by-voice. The ready-picked containers are then consolidated in the automated order consolidation buffer and directed to the packing area with large packing stations and parcel packing stations. The expansion in the logistics center will be put into operation in autumn 2022.

„Our goal is to perfectly fulfill the requirements of our customers and to advise them professionally and competently. The ability to delivery at short notice in the end customer business is therefore of utmost importance to us“, explains Alexander Kalkbrenner, managing director at AKF. „Since we have been working successfully with the existing system for 10 years, we decided to commission Klinkhammer again for the redesign of a future-oriented logistics concept. “ AS one of the most successful dealers for spare parts and accessories for Simson and MZ, AKF continues to invest in the growth market of e-commerce and logistics.