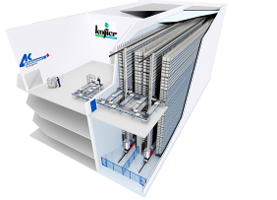

In Zams, Austria, a new logistics center of the Landeck-based traditional company Kofler will be built. Kofler is one of the leading suppliers of fresh food for hotels and restaurants in Tirol. The logistics center integrates an automated 20 meter high deep-freeze warehouse with order picking area as well as pick-by-voice-operated cold and dry storage areas. The core is the au-tomated tray warehouse for temperatures down to between -18°C and -24°C featuring 2 aisles, planned by the intralogistics specialist Klinkhammer. For this purpose, the architecture office thurner | mair bau.studio has developed a logistics center across several floors with 31 truck loading gates.

Regional specialties and exotic products at arctic temperatures

Kofler, a family-run company in the third generation, has been active as a wholesale supplier for 75 years. Dedicated employees ensure a smooth process from product procurement to delivery using the own fleet of 20 cold and deep-freeze vehicles. Overall, the conveniently located premises with direct highway access comprise 45,000 square meters. In a second construction stage, the 4-storey building will be extended by another three floors. Thereby, the enclosed space will reach a size of 145,000 m³. The wide product range of Gebrüder Kofler GmbH comprises more than 1,500 fresh, frozen and dry food products. About 80% of the products are purchased directly from the producer, such as regional specialties from the farmers of the Inn valley, or the well-known apple strudel of Ti-rol, but many exotic products from all over the world can also be found in the deep-freeze warehouse.

Flexible tray storage for various types of packaging

The existing manual deep-freeze warehouse featuring a capacity of 1,800 pallets ensures high deliv-ery reliability, but it has reached its limits with the planned future growth, because frozen food prod-ucts enjoy increasing popularity. As deep-freeze storage space is expensive, the aim is to maximize the number of products stored compactly on the smallest possible area. Due to various packaging designs in the frozen food product range of the company Kofler, a tray is used as loading aid. The temperature-controlled automated deep-freeze warehouse offers storage space for more than 24,000 tray storage locations with different carton height classes in order to optimize storage density. The order picking area is thermally separated from the actual deep-freeze area and positioned in an area with controllable ambient temperature. The loss of cooling and the introduction of heat into the deep-freeze warehouse are kept at a minimum to increase energy efficiency.

„We opted for a warehouse automation because minimizing the storage area at maximum space utili-zation is crucial for an energy-efficient operation“, explained Martin and Anton Kofler, managing di-rectors of Gebrüder Kofler GmbH. „Finally, we were able to benefit from the experience of Klinkhammer gained in the wholesale distribution to hotels and restaurants and optimize proven con-cepts to our needs and plan individually with Klinkhammer.

The warehouse is inerted and operated with a reduced oxygen content in order to minimize the risk of fire. The pre-zone circuit connects the storage and retrieval conveyors in the inerted storage area with the manual order picking area. Picking takes place according to the goods-to-man principle. The workplace is ergonomically designed. Automatic control checks such as weight-, height- and barcode-controls are performed at the conveyors.

Icy cooling technology

Deep-freeze warehouses require a special technology, which Klinkhammer provides for the ware-house. Mechanics, electrics and control components have to be designed for icy temperatures. Thus, the technology remains “cool” and long-lasting. From the oil for gears suitable for cold temperature operation to heated sensors, cold-resistant sealing and plastics to deep-freeze-suitable industrial PCs, much attention must be paid to ensure lifetime durability. KlinkVISION controls and visualizes the complex material flow systems. In an automated deep-freeze warehouses of Klinkhammer, pro-cesses are constantly monitored and transparently visualized. Completion of the plant is planned for the first quarter of 2021.

Data and facts:

- 2-aisle, double-deep automated deep-freeze warehouse with more than 24,000 tray storage loca-tions

- Different height-optimized tray storage locations

- Order picking station in temperature-optimized work area

- Klinkhammer warehouse management including material flow control