By clicking on "Continue" you leave our website and you will be redirected to YouTube. Here you will find our privacy policy.

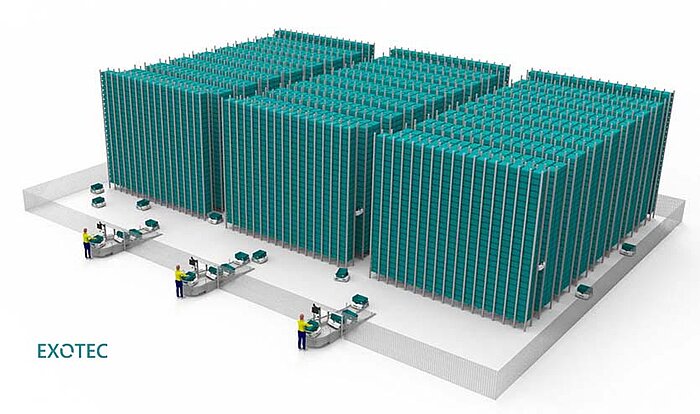

Skypod®-Systems, autonomous warehouse robot systems by Exotec® integrate two functions. They combine the possibility of free navigation at ground level and vertical operation in the rack. With this double function, the robots handle the storage and retrieval directly in the rack, such as shuttles, as well as the delivery of containers to the order picking workstations.

Higher system performance

• Use of additional robots

Higher storage capacity

• Extension of the racking system without downtimes

Higher picking performance

• Setup of additional workstations

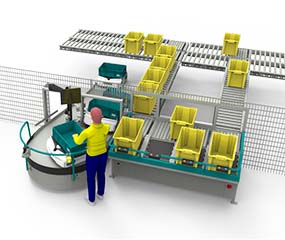

Transport on the ground & storage and retrieval in the rack

Thereby, the Exotec system offers with Skypod a real alternative to conventional shuttle systems as the statically installed conveyor pre-zone and the shuttle lifters are no longer necessary. Typical fields of application of the Exotec system are multi-channel retailers and e-commerce warehouses, which require flexible, scalable systems due to a highly fluctuating order situation. The Skypod routes are coordinated centrally by artificial intelligence and the robots are able to recognize each other. They are operated by lithium batteries. The Exotec system covers the low, medium and high performance range. The Skypod robots can be very fast, reaching a speed of up to 4 m/s.

• Klinkhammer is integration partner of Exotec® in the German-speaking region and in Eastern Europe.

• System integration with digital networking of different storage systems, from goods receipt to dispatch

• Competent Klinkhammer-service – one face to the customer

• The holistic solution for your logistics processes

Load:

Speed:

Obstacle detection:

Navigation:

Energy:

Charge:

Charging cycle:

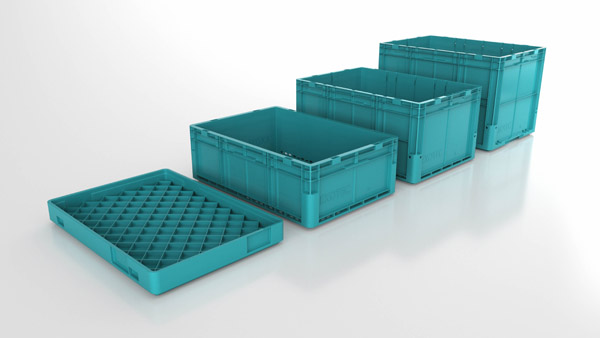

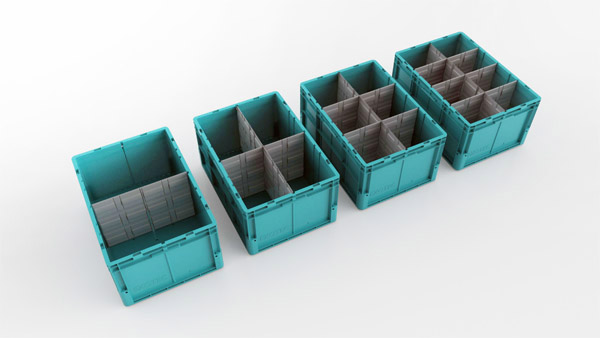

Container:

capacity 30 kg

4 m/s

laser scanner

scanner, Points Cloud Computing

lithium battery

booster charging station, availability 7/24

5 min/h per robot

650 x 450 x 220 mm, 320 mm, 420 mm height, sectioning in up to 8 compartments

By clicking on "Continue" you leave our website and you will be redirected to YouTube. Here you will find our privacy policy.

• No static, maintenance-intensive conveyor pre-zone

• No performance-limiting shuttle lifters

• Robot maintenance during ongoing operation

• Can be expanded at any time

By clicking on "Continue" you leave our website and you will be redirected to YouTube. Here our privacy policy.

By clicking on "Continue" you leave our website and you will be redirected to YouTube. Here our privacy policy.