Nuremberg/Munich (24.07.2015) - The company Schaltbau GmbH, one of the leading manufacturers of electromechanical products for traffic equipment and industrial applications, modernizes its control system for the existing tote storage system and the associated connection to the conveyor system..

Founded in 1929, Schaltbau GmbH manufactures electromechanical products for traffic equip-ment and industrial applications. The product range comprises plug connectors, snap switches, contactors and railway-specific products. Schaltbau GmbH is part of Schaltbau Holding AG with an annual turnover of 429.6 million euros and 2651 employees. The company has nine subsidi-ary companies and foreign representations in France, the UK, the USA and China and works together with more than 60 distribution partners. Around 480 staff members are working at the locations in Munich, Velden and Aldersbach.

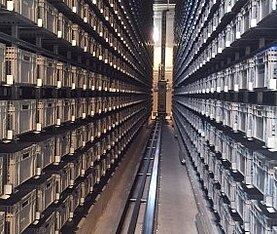

With the objective in mind to guarantee technical availability and to minimize downtimes, the existing automation technology in the high-bay warehouse zone and of the conveyors is being modernized and upgraded to the latest technological standard. Two automated racking aisles of a small parts storage system and the associated conveyor periphery – including crossways transfer cars – are retrofitted and modernized such to feature state-of-the art control technology. The intended outcome: an improved system performance and system availability and a guaranteed future spare parts supply.

A master control station equipped with consistent, standardized, modern plant visualization by Klinkhammer for the automatic small parts storage system now allows easy troubleshooting. This way, the operating and service staff is supported and downtimes are minimized thanks to a fast alarm diagnosis. A SMS message service quickly and reliably informs the technicians on site about malfunctions. Beyond that, a service expert of the Klinkhammer Group at Nuremberg is able to externally access the visualization and thus to intervene directly in the system around the clock.

The existing drives, servo inverters and programmable logic controllers of both storage and retrieval cranes and of the crossways transfer car are replaced by control hardware of the latest generation. Both the storage and retrieval cranes and the conveyors are equipped with a mobile touch panel including the associated plug-in ports. Scanners as well are replaced by fieldbus-ready devices. After that, the controller is completely reprogrammed. The retrofit is schedule to take place over the Christmas holidays without disturbing the ongoing operation. In the future, maintenance and service will be done by one provider – the Klinkhammer Group.