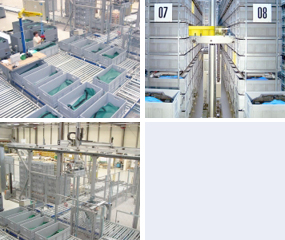

This term describes the process of contact-free reading of and writing onto a data carrier by means of radio technology. The tag, also called transponder (transmitter [sender] and responder [replying unit]) contains data on the product or load carrier. At Dräxlmaier, the chip is integrated in the bottom of the transport container. It identifies the container and receives product data. At delivery, order data is entered for the JIT/JIS application. For one of the emergency concepts, the transponder also contains information on the destination for the conveyor PLC which therefore can execute the transport also without MFC.

The RFID transponder technology offers many advantages

Being not subject to wear and tear is certainly the great advantage of RFID. No bar code which is unreadable or gets lost. If required, the tag is written with new data. Additionally, automated processes can take place which otherwise are carried out by an employee such as the identification of Kanban boxes for refilling, from palletizing to automatic dispatch. For a transponder, it is also of no importance whether being transported lengthwise or crosswise - it must be only within the magnetic field of the reading unit. This way, handling becomes easier and faster thanks to the digitalization.